It’s much easier to use endless ratchet straps. These one-piece straps don’t have hooks.

I recently added a slab of concrete in the backyard of one of my rentals. Unfortunately, I made some mistakes along the way. Specifically,

We first removed a lot of dirt and gravel by scooping it into some buckets. We did this so the 3.5″-thick concrete slab would be level with the existing concrete slab.

I rented a pick-up truck from U-haul and put tarp on the truck bed to protect it. This also made cleanup easier because I could pull the tarp off the truck along with any remaining dirt on it.

Driving with a full load of dirt made the truck swerve slightly at higher speeds so we took local roads to go to the city dump.

At the dump, we just shoveled the dirt onto the ground. The problem was the cost to dump dirt and gravel. If I had paid by weight, the cost would have been about $500. The clerk instead calculated the cost by volume, which lowered the cost to $372.

After making one trip, I regrettably thought I needed to remove more dirt and gravel. So, we made another trip and I spent another $372. After creating the wood form for the concrete slab, we realized that we had removed too much dirt, which meant I needed 2.5 times the amount of concrete I should have needed.

I called around to get quotes from concrete contractors. The slab dimensions would be 9′ x 15.5′ (140 sq ft). The first contractor quoted me $2000, but then lowered it to $1700. He quoted me without seeing the work area.

The second contractor came to see the work area and then quoted me $1500. That meant his rate was $1500/140 = $10.71 / sqft. According to one source, the cost in the California Bay Area to install a concrete slab including materials and delivery is between $8 to $14 / sqft. Therefore, I went and chose the 2nd contractor and paid $10.71 / sq ft.

The contractor came and created the wood form. I first compacted the soil using a hand tamper and put down some pond liner where the edge of the concrete would be. Half of the pond liner would be under the concrete. The other half would be under rocks or mulch. The reason for doing this is so that weeds don’t grow along the edge. I left a 30″ gap between the old concrete slab and the new one for rainwater to drain into the ground.

This is when I realized that I had removed too much dirt and gravel. I wanted the top of the new concrete slab to be level with the existing concrete slab in the backyard. Using a level, the contractor drove a wood stake into the ground and marked on it where the top of the 2×4 wood form would go. Screws were screwed through the vertical stakes into the 2x4s. Wood stakes were also used at an angle. This was necessary because without them, the weight of the concrete could push the vertical stakes and cause a deformity in the form. As you can see in the photo below, too much dirt and gravel had been removed, so the contractor had to put another 2×4 below the first set of 2x4s. This resulted in a slab thickness that was approximately 3.5″ x 2 = 7″ (one 2×4 is actually 1.5″ x 3.5″). That’s twice as much as is needed for a standard slab and therefore twice the amount of concrete would be needed.

Furthermore, I wanted the slab to slightly slope towards the long edge so that rainwater could flow into the ground rather than puddle on the slab and weaken it (concrete is porous). To determine the slope, the contractor used a level on the 2×4 and tilted it slightly before screwing it into the wood stakes. Then, he used a red chalk string to snap a line on the wall, marking the desired height of the slab along the wall. Since the red chalk wasn’t clear, he went over parts of it with a black marker as shown below.

To reinforce the concrete, the contractor added rebar. He cut the rebar with a reciprocating saw and metal blade.

They then tied the rebar together in what appeared to be plastic-coated wires or electrical (romex) cable.

Instead of buying a bunch of bags of concrete and mixing them with water, the contractor ordered a truck to come and deliver premixed concrete.

The premixed concrete flowed down a channel into a wheelbarrow.

One person transferred the concrete to the work area while the other used a trowel to trowel the concrete.

Occasionally, they’d pull the rebar up so that it would settle in the middle of the slab rather than at the bottom.

After pouring all the concrete and moving it into place using a hand trowel, this is how it looked.

The contractor then used a float attached to a pole to create a smooth surface. If necessary, he would spray a mist of water to soften the concrete.

On the truck, the concrete supplier could see how much concrete was supplied. As you can see below, I needed a total volume of 2.66 cubic yards. People in the business would just say “yards”, which makes no sense since that’s a measure of length rather than volume. What they really mean is cubic yards.

The unit cost of concrete is $169 / cu yd (cubic yard). Fortunately, the concrete supplier put down 2.5 cu yds rather than 2.66 cu yds to save me a little money. Had I not removed so much dirt and gravel, I could have only needed 1 cu yd for a 3.5″ thick slab. Instead, the resulting slab is now 6 to 6.5″ thick.

For small loads, the concrete supplier charges an extra $80 for 1 to 2.75 cu yds or $60 for 3 to 4.75 cu yds. Again, the supplier gave me a small discount by only charging me an extra $60 instead of $80. Then, there’s the delivery fee, which costs $80. The total cost for just the concrete was $607.91.

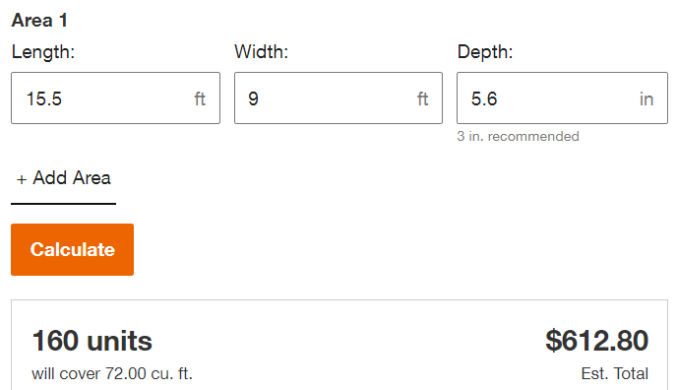

For comparison, if you buy bags of concrete at Home Depot, transport it yourself, and mix it with water, you’d pay $612.80 + 10% tax = $674 for the same 2.66 cu yds (72 cu feet) of concrete.

The concrete supplier cleaned his truck and washed the surrounding area.

The contractor then used an edging trowel to create a rounded edge.

He also used a special tool to create a control joint line.

Once the concrete dries a bit, he’ll give the concrete surface a brushed texture so it’s not slippery smooth. Then, tomorrow, he’ll remove the wood form.

Unfortunately, the contractor didn’t do a good job. There were some uneven areas that drove me crazy. To fix this, I used a 7″ concrete grinder.

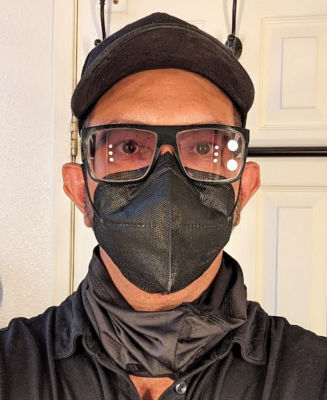

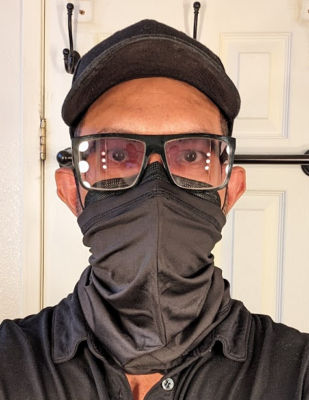

IMPORTANT: concrete dust is very dangerous if inhaled! Always wear protection.

When grinding concrete, move relatively quickly and in a circular motion to avoid creating uneven spots.

Raw concrete doesn’t look that great. To beautify it, I’ll apply some epoxy to it. In order for the epoxy to stick, the smooth surface needs to be etched. The easiest way to do this is by renting a flooring tool with the Diamabrush concrete prep attachment. In my case, the surface wasn’t smooth, so I was able to skip this step.

Since cars will not go on my slab, I’ll apply some 1-part epoxy. I like this one in silver gray:

It’s very easy to apply. Just roll it on using an epoxy roller. To prevent slipping, add anti-slip floor additive to the epoxy.

Last week, I had solar panels installed on my roof. The installers secured their ladder to my roof / eaves using the Guardian Fall Protection “Ladder Stability Anchor”.

The way it works is you clamp the clamp onto your eaves, secure the hooks to the hole on the clamp, then wrap the straps around your ladder, securing it using the hook and loop velcro.

It’s a simple idea, but the price is $90. It just went on sale for $56, but that still seems overpriced. Not sure why Harbor Freight hasn’t created a cheaper alternative.

Anyway, you can probably make your own for much less by just using

For an easy-to-transport ladder, this telescoping ladder ($160) is great.

If you need this for your own home and there is one spot you would always use to get on the roof, and if you want a more secure solution, replace the C-clamp with a large screw eye or eye bolt with nut and use the ratchet straps instead of the cam buckle strap.

The old sink was the top-mount kind. Water kept leaking behind the sink into the base cabinet.

The same quartz countertop was on sale from $500 to $400 (8-foot-long slab).

Found a Mexican guy in the parking lot and got him to transport and install the countertop.

The slab was leaning against the side of the truck and secured using a rope.

To remove the old countertop, I placed a towel on top of it and hit it with a sledgehammer to break it up into small pieces without pieces flying everything.

It actually didn’t take long to remove the old countertop.

I then unscrewed the old plywood and threw it away.

For an undermount sink, you need at least 19/32″ thick plywood. I had Home Depot cut a 4×8′ plywood sheet in have to make two 2×8′ sheets.

I was able to fit both 2×8′ sheets in my car 🙂

I screwed the plywood into the base drawers. There was moisture damage and a hole in the wall which I had to fix.

I patched up the hole and smoothened the wall surface.

That 19/32″ thick plywood should be strong enough for the undermount sink.

I found an 18-gauge undermount sink (30″ x 18″ x 9″ deep) at HD Supply for $175.

The installers cut a hole in the plywood for the sink. They should have used a jigsaw to make the hole.

They cut the countertop outside because it produces a lot of dust.

First, they cut the slab to length. Water was needed to keep the blade from getting too hot and keep dust from going everywhere.

Here, he’s cutting the hole for the sink using an angle grinder. I think he should have used a circular saw to make a straighter cut.

He then polished the edges while his assistant squirted water.

The sink didn’t come with a paper template for cutting a hole in the plywood and countertop. An easy way to mark an outline where to cut the whole is by turning the sink over, sticking your hand into the drain hole, and using a pencil, mark the perimeter.

I had them drill 3 holes: one for the faucet, one for a soap dispenser, and one for the dishwasher.

They put extra strong construction adhesive along the perimeter of the sink hole where the sink lip will sit. They also put it on the plywood in various places to secure the countertop to the plywood.

They then glued the backsplash to the wall and applied silicon to the joint.

When smoothening out silicone or caulk, you should always use a tool like the Husky 3-in-1 caulk tool. The triangular edge makes for a perfect finish.

When installing the p trap, I chose the flexible kind that you can cut to length. It’s much easier than fooling around with metal or PVC drain parts and it never leaks.

And this it how it came out. Not bad at all.

And here’s a close-up of the sink area.

The information below is primarily for California. However, much of it still applies nationwide.

The sun essentially provides an endless supply of energy. In fact, with the amount of sunlight that hits the earth in 90 minutes, we could supply the entire world with electricity for a year — all we have to do is catch it!

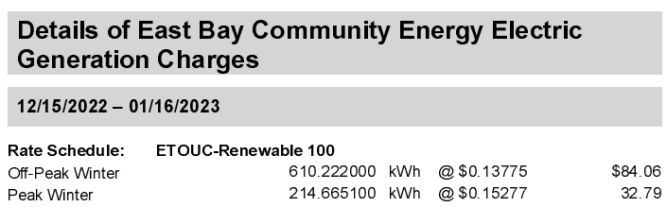

The price of electricity is measured in cents per kilowatt-hour (kWh). According to the US Bureau of Labor Statistics, the national average price for electricity in July 2022 was $0.166 per kWh.

Seattle had the lowest price of any major metro area at $0.118 per kWh while San Diego, Houston, Urban Hawaii, and San Francisco all had electricity rates above $0.311 per kWh.

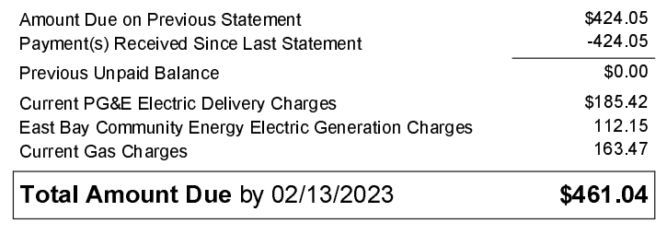

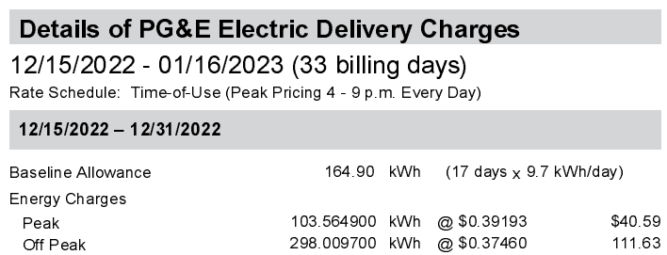

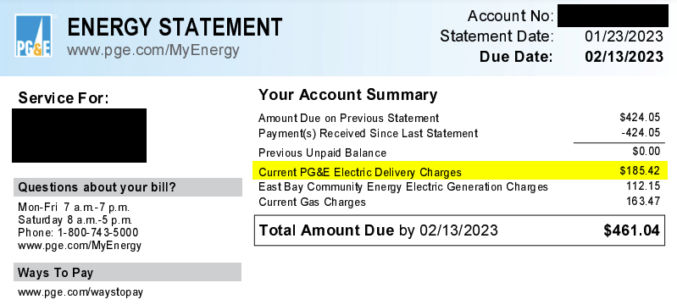

In January 2023, my PG&E energy bill was $461.04. The electricity portion alone was about $300. Looking at the bill below, the electricity portion is divided into two:

The delivery rate averages $0.38 / kWh.

The generation rate averages $0.14 / kWh.

The cost to deliver electricity is way more than the cost to generate it. Adding the two rates up, we get $0.38 + $0.14 = $0.52 / kWh.

According to the California Energy Commission, 66.4% of California’s energy comes from non-renewable sources and 33.6% comes from renewable sources. 14.2% comes from solar.

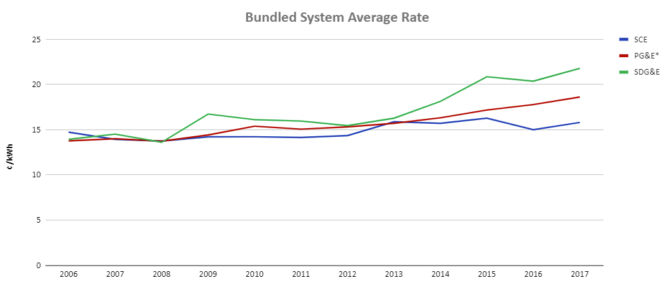

Factoring in discounts and the 30% federal solar tax credit, the average price of solar is between $0.06 and $0.08 per kWh.

In the last 20 years, the price of grid energy has increased by 2.79% per year on average, according to the U.S. Energy Information Administration (EIA). And the EIA is projecting a 2.54% increase from 2022 to 2023.

The cost of solar panels has gone down over the last decade.

Solar panels are modular pieces, usually rectangular in shape – approximately 3’ by 5’ long.

| PERC | Monocrystalline | Polycrystalline | Thin-film | |

|---|---|---|---|---|

| Initial Cost | Highest | High | Middle | Highest to lowest: CIGS CdTe a-Si |

| Efficiency | Highest (5% more than monocrystalline) | 20% and up | 15-17% | CIGS: 13-15% CdTe: 9-11% a-Si: 6-8% |

| Appearance | Black with rounded edges | Black with rounded edges | Blue with square edges | Depends on the thin-film variant |

| Advantages | Requires least space. Most efficient. Highest power capacity | Less expensive alternative to PERC panels without the passivating layer | Middle option in terms of cost, efficiency and power capacity | Lowest cost, Easier to install |

| Disadvantages | Most expensive initially. Some earlier panels suffered from light and elevated temperature induced degradation | High initial cost. Low yield in the manufacturing process | Low heat tolerance, not suitable in hot environments | Shorter lifespan than crystalline panels, requires more space, Least efficient |

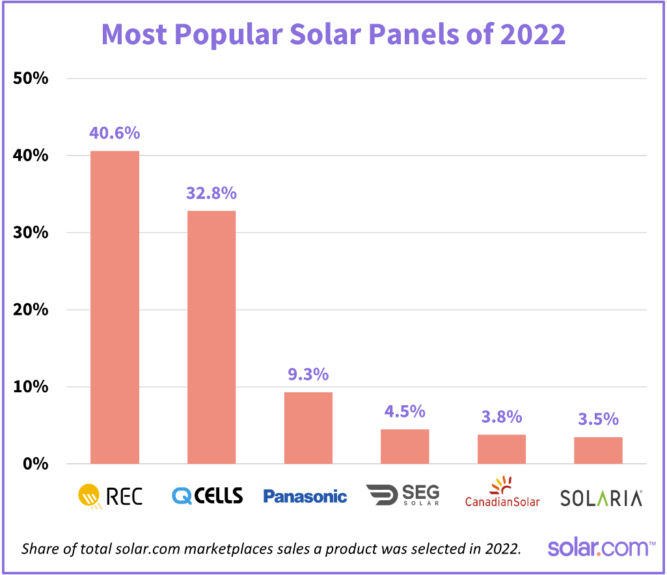

From January to December 2022, manufacturers REC and Hanwha Q CELLS had the most popular panels for residential solar.

There are nearly 50 REC models and 80 Q CELLS models available through the solar.com network, ranging in wattage from 265W to 450W (although 400W is now considered the norm, and anything under 365W is considered rare).

REC and Q CELLS back their panels with a 25 year product warranty.

| BRAND – HQ LOCATION | PANEL | MANUFACTURE LOCATION | WHY SOLAR.COM LIKES IT |

|---|---|---|---|

| Silfab – Canada | SIL Mono series | Bellingham, Washington | Durable, >20% efficient |

| Q Cells – Korea | Q. Peak Duo Series | Dalton, Georgia | Durable, >20% efficient |

| Mission Solar – US | MSE PERC series | San Antonio, Texas | Qualifies for Buy American Act |

| Solaria – US | Power XT series | Fremont, California | >20% efficient, superior shade performance |

| BRAND – HQ LOCATION | PANEL | WHY SOLAR.COM LIKES IT |

|---|---|---|

| Sunpower – San Jose, CA | A-series | Up to 22.8% efficiency, 25-year warranty, built-in AC inverter |

| Sunpower – San Jose, CA | X-Series | Up to 22,7% efficient, extremely low degradation rate, 25-year warranty |

| SEG – Pleasanton, CA | SEG-410-BMD-HV | 21.25% efficiency, 25-year warranty |

| Aptos Solar – Santa Clara, CA | DNA-120-MF26-370W | 20.29% efficiency, durable, 30-year warranty |

| PANEL | DEGRADATION RATE | PERFORMANCE WARRANTY |

|---|---|---|

| SunPower X-Series | 0.2% to 0.25% per year | 92% of minimum peak power after 25 years |

| Panasonic EverVolt® Photovoltaic series (EVPV) | No more than 0.25% per year | 92% of maximum power after 25 years |

| REC Alpha series | No more than 0.25% per year | 92% of nameplate power output after 25 years |

Residential solar panels typically range between 15% and 20%, with the industry leading panels pushing 23%.

| MANUFACTURER | MODEL | EFFICIENCY RATING |

|---|---|---|

| SunPower | A-series | Up to 22.8% |

| SunPower | X-series | Up to 22.7% |

| Panasonic | EverVolt® Photovoltaic series | Up to 22.2% |

| SunPower | M-series | Up to 22% |

| REC | Alpha series | Up to 21.9% |

| Silfab | Elite series | Up to 21.4% |

| SEG | SIV AC Module Series | Up to 21.25% |

| Silfab | X series | Up to 21.1% |

| Solar World | Sunmodule series | Up to 21.1% |

| S-Energy | SL40-60MCI-370 | 21.04% |

There are a number of factors that influence solar panel efficiency. They include:

Solar panels still generate electricity on cloudy days, although not as effectively as sunny days. Solar panels can capture both direct and indirect light (light that shines through clouds), but perform at around 10-25% of their normal efficiency when it’s cloudy.

Cloudy days can be beneficial, however, as rain washes the panels and increases their overall efficiency.

If you’ll have solar panels that are visible, e.g. from the street, you may want to pick ones that look good. Most solar panel frames are anodized aluminum and come in silver or black. Choosing a black frame can enhance the look of your system greatly. You may be interested in getting “all black” panels, where the frame, backsheet, and cells are all the same black color.

Most inverters have warranties ranging from anywhere between 5 and 10 years, though some can be extended to 25 years.

There are 2 types of inverters.

Pros

Cons

Pros

Cons

Power optimizers can optimize the power before sending it to a central string inverter.

Pros

Cons

Peak (max) efficiency and weighted (average) efficiency

If the solar panel DC output exceeds the max power rating of the inverter, the excess power is clipped (wasted).

It’s normal for the DC system size to be about 1.2x greater than the inverter system’s max AC power rating. For example, a 12 kW solar PV array paired with a 10 kW inverter is said to have a DC:AC ratio — or “Inverter Load Ratio” — of 1.2.

In order to ensure your solar system is producing energy normally, it’s important to make sure your solar panels are paired with an energy production monitoring system.

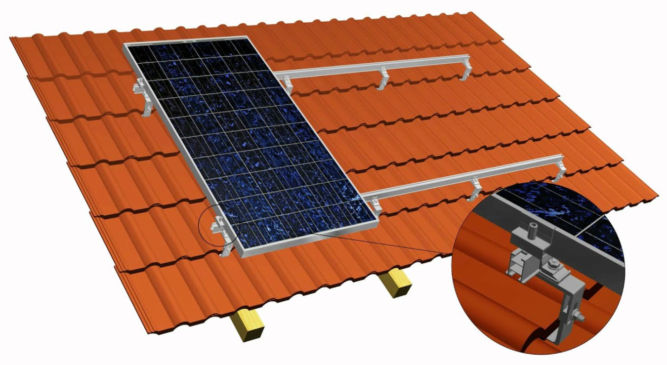

It’s important to make sure your racking system, if roof-mounted, is properly flashed and sealed to ensure your roof is well-protected against the elements.

| Roof Material | Note |

|---|---|

| Composite shingles | Most common roof material. Easy and cheap to install solar panels on them. |

| Clay Tiles | More expensive to install than all other roof types. |

| Concrete Tiles | Cheaper to install than clay tile roofs but more expensive than shingles. |

| Metal Standing Seam | Easy and cheap to install. |

| Tar and Gravel | More expensive to install than clay tiles. |

| Wood | Not recommended for installing solar panels |

Most major solar manufacturers including REC, SunPower, and Panasonic offer warranties that guarantee a certain level of output over 25 years, and some companies are beginning to offer 30-year warranties. The performance warranty guarantees that a panel’s output capacity will not drop by more than 0.7% per year, or less than 20% over 25 years.

Solar panels don’t disappear when they reach the end of their warranty, their production capacity just slowly degrades over time.

The average energy needs of a U.S. household is a 6.62-kW solar system to match the 9,000 kWh of average energy usage by U.S. households each year. And, the typical solar panel makes 320 watts of electricity in ideal sunny conditions. Here’s how many solar panels that equals.

Divide 6.62 kW (the system size) by .320 kW (the wattage per panel) = 20.69—rounded up that’s 21 panels. While your home is far from average, this is how you can calculate your own rough estimate.

Solar panels are rated based on the watts they generate. The higher the wattage rating, the greater amount of power your solar installation will produce. Most residential solar panels have power output ratings from 250 to 400 watts, depending on panel size and how well they convert sunlight into energy. While higher power ratings are considered preferable, power output is not the sole factor in judging a solar panel’s performance.

For instance, two solar panels may each have a 15% efficiency rating, yet the power output rating of one is 250 watts and the other is 300 watts.4 The higher output may simply be due to the 300 watt panel’s larger physical size–rather than having a high efficiency or more advanced technology. Therefore, panel efficiency is a better indicator of solar panel performance than just power output for meeting your energy needs.

The solar investment tax credit (ITC) is a 30% tax credit that you are allowed to claim in the form of a deduction from your income taxes (after any available rebates) off the overall gross system cost, including any necessary upgrades to the main panel box upgrades in order to go solar.

In August 2022, the Inflation Reduction Act increased the tax credit from 26% to 30% and extended it until 2032. It also renamed it the Residential Clean Energy Credit (although most people still call it the ITC or solar tax credit).

So if you purchased a solar system worth $25,000 in 2022, you can claim a $7,500 deduction on your 2022 taxes that you file in early 2023.

The new and improved solar tax credit also applies to battery storage, whether or not it’s connected to solar. So you can claim the tax credit for adding battery storage to an existing solar system or for battery storage that’s not connected to solar at all.

Learn how to get your federal solar tax credit.

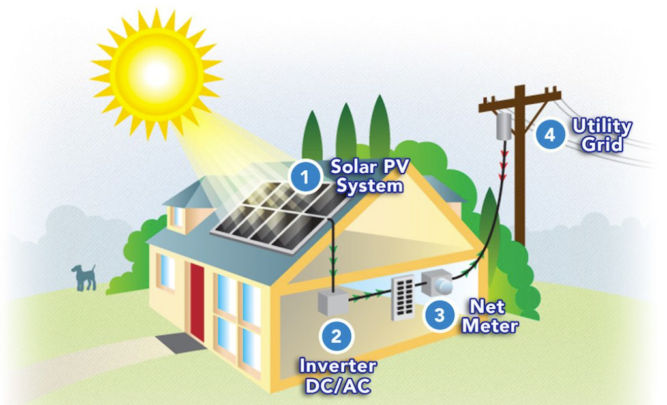

Net Energy Metering (NEM) is the policy that allows you to push and pull energy to and from the grid through your electrical meter. Traditional utility users pull energy from the main grid, use the energy in their home, and the meter counts how much is used. With solar, you will push your excess energy into the grid during the day and pull it out at night to use for lights, TV, A/Cm or anything else you may need. The grid functions as a bank storing your energy from your solar panels until you are ready to use it. With a battery backup system and secure power supply, you can use the energy from your system when the grid goes down.

If you don’t use all the energy your system produces in a day, that energy will roll over to the next day and so on. This happens day after day, month after month. This allows you to use all the energy you produce with your solar system. If you have higher usage months (AC, guests, holidays, etc) you draw from the extra energy credits you earned earlier in the year.

Once a year you “true up” with your utility where you settle the balance on your energy credit. If you consume more than you produce then you’ll pay the utility for the excess energy you pulled from the grid. If you produce more energy than you consume, the utility will compensate you for your excess energy at a below-retail rate.

In most cases, 1 kWh of electricity pushed onto the grid offsets 1 kWh of electricity pulled off the grid.

However, energy utilities are making a nationwide push to weaken net metering by paying less than retail prices for solar exports. Most notably, California’s NEM 3.0 reduces the export rates by over 75%.

NEM 3.0 Final Decision: The California Public Utilities Commission (CPUC) unanimously voted to approve NEM 3.0. Under NEM 3.0, customers of PG&E, SCE, and SDG&E with solar systems will receive an average of 8 cents per kWh for the excess power they push onto the grid. This is roughly 75% less than the average export rate of 30 cents per kWh under NEM 2.0. IOU customers have until April 13, 2023 to grandfather a new solar system into NEM 2.0 by submitting a complete interconnection application.

| SOLAR UNDER NEM 2.0 | SOLAR UNDER NEM 3.0 | |

|---|---|---|

| Monthly energy bill (previously $250) | $18 | $96 |

| Payback period | 4.6 years | 6.5 years |

| Lifetime savings | $116,680 | $73,620 |

| SOLAR UNDER NEM 2.0 | SOLAR UNDER NEM 3.0 | |

|---|---|---|

| Monthly energy bill (previously $250) | $162 | $239 |

| Down payment | $0 | $0 |

| Lifetime Savings | $110,308 | $67,248 |

| SOLAR UNDER NEM 2.0 | SOLAR UNDER NEM 3.0 | |

|---|---|---|

| Monthly energy bill (previously $250) | $123 | $200 |

| Down payment | $0 | $0 |

| Lifetime Savings | $105,844 | $62,784 |

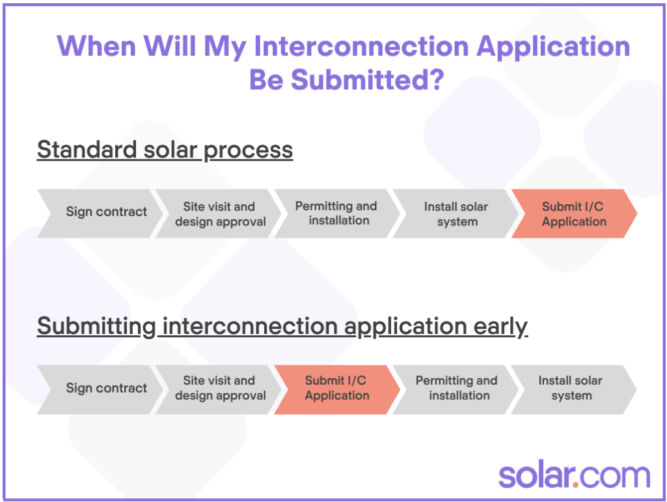

There are two steps required to grandfather a solar system into NEM 2.0.

Quick Note: NEM 3.0 is not retroactive. Existing solar systems will remain under their current net metering policy for 20 years from their interconnection date.

According to the final NEM 3.0 proposal, a valid solar interconnection application includes:

Typically, solar installers submit the interconnection application after the system has been installed. However, in response to NEM 3.0, many – but not all – companies are changing their operations process to submit as early as possible.

Since solar installations typically take 3-5 months to line up, it’s important to find an installer that has changed their process to submit interconnection applications early.

Beginning in January, you should be able to get emailed proof that you have been grandfathered within 2-3 weeks of signing the contract.

According to Zillow, nationally, homes with solar-energy systems sold for 4.1% more on average than comparable homes without solar power. For the median-valued home, that translates to an additional $9,274.

A 10-year study concluding in 2015 by the Lawrence Berkeley National Laboratory found that solar panels add around $4 per watt of capacity installed – or $4,000 per kW. Here’s how that adds up based on the size of your system:

| SOLAR SYSTEM SIZE | INCREASE TO HOME VALUE FROM SOLAR PANELS* |

|---|---|

| 4 kW | $16,000 |

| 5 kW | $20,000 |

| 6 kW | $24,000 |

| 8 kW | $32,000 |

| 10 kW | $40,000 |

Factors to consider when choosing an installation company are

Installers who are NABCEP-certified are knowledgable and have solar experience. North American Board of Certified Energy Practitioners (NABCEP) certification requires installers to

Solar PV systems require almost zero maintenance. Be wary of these ‘maintenance packages’ as they are often overpriced.

To determine the size of your solar system and the number of panels you’ll need, you need to know how much electricity you use on average per day.

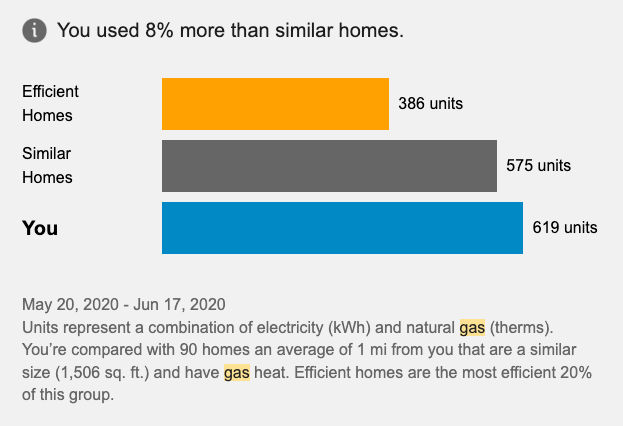

Looking at my PG&E electricity usage and cost over the last 12 months below, we find that my average monthly electricity usage was 527 kWh. But, since I bought a plug-in hybrid and started charging my car in October, I’ll take my average to be from the last 3 months, which is 709 kWh. Of course, the last 3 months of the year were cold and daylight ended early at around 5 PM, so my electricity usage went up for other reasons as well. We’ll assume my average monthly electricity needs is 700 kWh and my annual usage would be 700 x 12 = 8400 kWh / year.

| Start Date | End Date | kWh | Cost | Note |

|---|---|---|---|---|

| 2022-01-18 | 2022-02-15 | 656.84 | $168.47 | |

| 2022-02-16 | 2022-03-17 | 577.84 | $134.91 | |

| 2022-03-18 | 2022-04-18 | 494.57 | $102.54 | |

| 2022-04-19 | 2022-05-17 | 358.42 | $68.48 | |

| 2022-05-18 | 2022-06-15 | 372.67 | $82.26 | |

| 2022-06-16 | 2022-07-17 | 443.17 | $110.39 | |

| 2022-07-18 | 2022-08-16 | 416.57 | $103.91 | |

| 2022-08-17 | 2022-09-15 | 452.3 | $115.19 | |

| 2022-09-16 | 2022-10-16 | 420.99 | $94.50 | |

| 2022-10-17 | 2022-11-15 | 604.61 | $136.73 | Includes charging EV |

| 2022-11-16 | 2022-12-14 | 695.44 | $162.45 | Includes charging EV |

| 2022-12-15 | 2023-01-16 | 824.89 | $185.42 | Includes charging EV |

| Average | Last 12 months | 527 kWh | $122 | |

| Average | Last 3 months | 709 kWh | $161 |

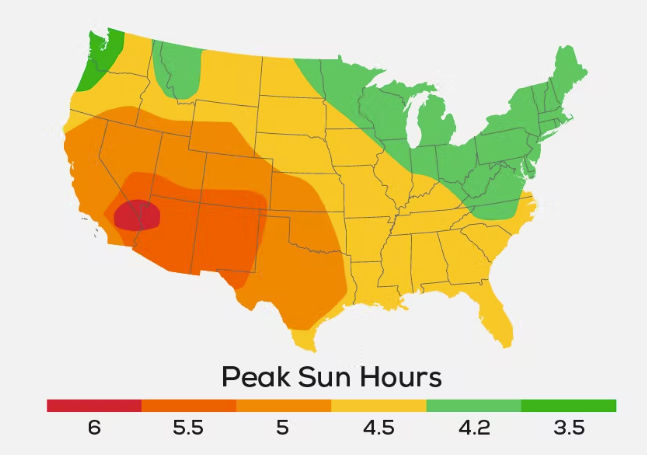

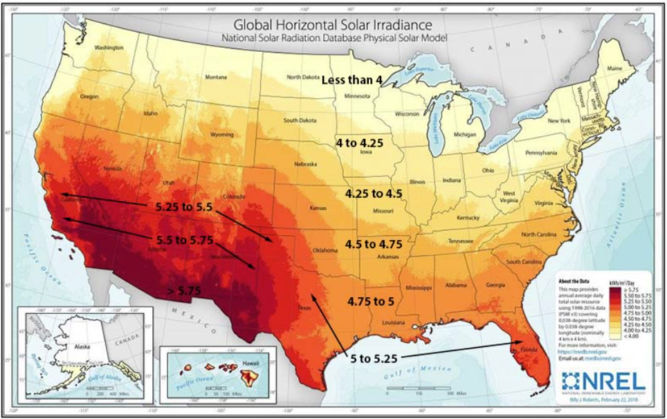

To continue this analysis, we’ll need the peak sunlight hours where I live. According to the map below, my peak sun hours is 5.

| A | Monthly electricity usage | 700 kWh / month | |

| B | Daily electricity usage | 24 kWh / day | A/30 |

| C | Hourly electricity usage (kWh) | 1 kWh / hour | B/24 |

| E | Solar panel system output needed per day | 5 kWh / day | F * peak sun hours (5) |

So, the solar panel system size I would need is a 5 kW system. But, since solar panels don’t operate at maximum efficiency 24 hours a day, we’ll add a cushion of 25%. That brings the system size to 5 kW x 1.25 = 6.25 kW.

The average solar panel produces 400 W. So, the number of panels I would need is 6250 / 400 = 15.6 panels.

For a 6 kW size, I was quoted $25,820. If I apply the 30% federal tax credit, I’d get $7,746, which brings the effective cost to $18,074. Since the minimum lifetime of the solar system is 25 hours, then we can calculate the cost per kWh as $18,074 / 25 years / 365 days / 24 hours = $0.08 / kWh. That’s a lot cheaper than my current electricity rate of $0.52 / kWh (PG&E generation + delivery rate).

Since my monthly electricity needs are 700 kWh. Then we can compare costs as follows:

| Cost / month | Cost / 25 years | ||

|---|---|---|---|

| Solar with 30% tax credit | 700 kWh * $0.08 | $56 | $16,800 |

| Grid | 700 kWh * $52 | $364 | $109,200 |

As you can see, going solar saves a ton of money. And that doesn’t even include the rising cost of electricity from the grid, which averages 2.2% per year.

This means that the lender will fund the full amount of the loan, but only collect payments based on 70% of the outstanding balance during the first year or so. This amounts to a 30% discount on your payments for the first 12-18 months and makes Day One savings greater than on a traditional loan.

After the 12-18 months is over, the homeowner is expected to pay down the loan balance by the amount of the tax credit.

In the example used earlier, the homeowner would receive a $20,000 loan but only pay interest on $14,000. If at the end of the 12 month grace period the homeowner fails to pay back the tax credit amount, then the lender will start charging interest on the $6,000 portion from that point forward.

Combo loans are independently financed. There are two separate loans.

The first loan is for 70% of the contract price, which has an interest rate (for which the homeowner qualifies). The second loan covers the remaining 30% of the contract price.

This second loan is meant to equal the federal tax credit amount and typically lasts for 18 months with 0% interest. If this amount is not paid off in that allotted time frame, the balance adopts the same APR as the first loan, whatever that may be.

Examples of combo loan financiers:

Some lenders tout extremely low nominal rates (some as low as 1.89%). They don’t tell you is that there is something known as a ‘dealer fee’ that can run as high as 17%.

Make sure you check the following:

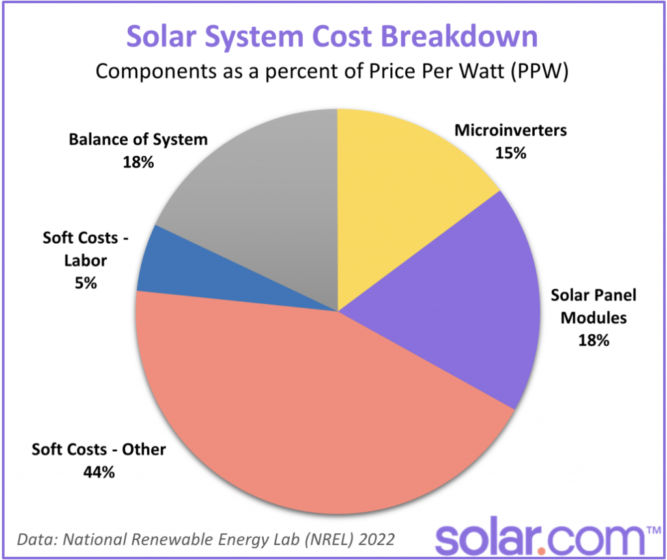

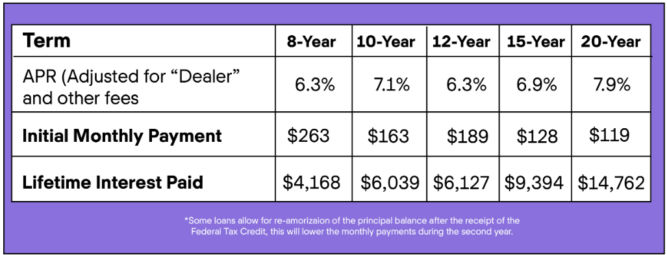

The table below compares monthly payments and lifetime interest paid for a $20,000 loan at different terms and APRs.

The most popular loan with Solar.com customers has a 12-year term, no pre-payment penalties, and interest rates of 2.99-4.99% depending on your credit score. The 12-year term is common because for most customers, their monthly loan payment is equal to or less than their current utility bill.

The more sun your solar panels get, the more money they can save you.

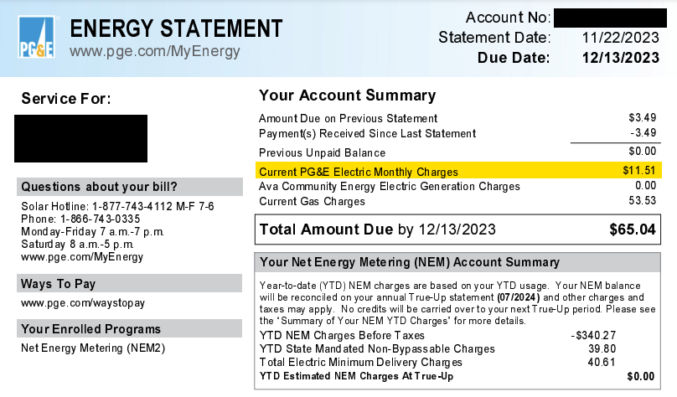

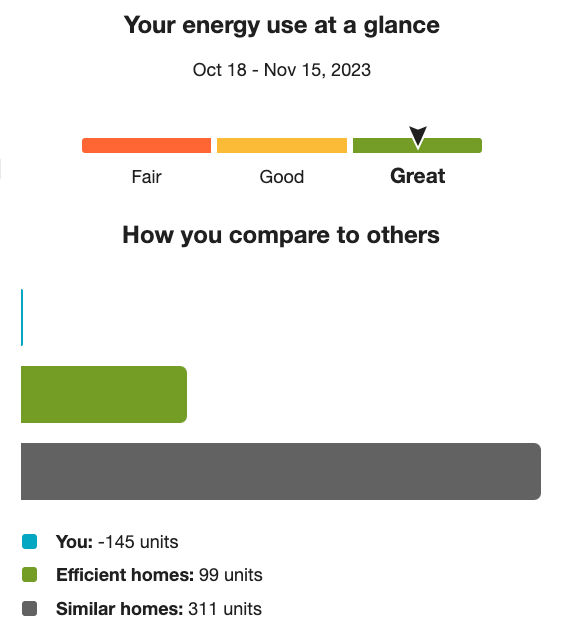

After installing solar panels, my electricity bill has gone down significantly.

It’s January 9, 2023, and it’s cold here in California. Sure, it’s nothing compared to the freezing temperatures in other parts of the country, but still, it can get pretty chilly in the evening and early morning.

And as the temperature drops, my energy bill goes in the opposite direction.

On top of that, high inflation has made everything, including energy, even more expensive.

Despite having an energy-efficient gas furnace, using it to heat up a 1600-square-foot house still seems more expensive than it should be. Plus, even if heating the entire house was inexpensive, it seems wasteful since many parts of the house are not always actively used. Though I have a gas furnace, according to EnergySage, the average wattage of an electric furnace is 10,000 to 50,000 watts. For comparison, my space heater uses 1500 watts. That makes sense since it plugs into a 120V / 15A outlet, which can support a maximum of 1800 watts before tripping the circuit breaker. And for another comparison, I have an electric throw (62″ x 50″ Microplush Electric Throw Blanket Leopard/Black – Biddeford Blankets) that, according to the label, uses 130 watts. A king-size electric blanket will use up to 200 watts. Personally, I actually find the electric throw more comfortable than the space heater and central furnace when I’m stationary (watching a movie or sleeping).

| Electric blanket | 130 – 200 watts |

| Space heater | 1500 – 1800 watts |

| Electric furnace | 10,000 to 50,000 watts |

According to my PG&E bill, my electricity cost is

Assuming I run a 200W electric blanket and an 1500W space heater for 3 hours a day during peak hours, I can find the cost for each using the formula:

W/1000*H*CPKWH

where

| Device | Math | Cost/day | Cost/month |

|---|---|---|---|

| Electric Blanket | 200/1000*3*0.39193 | $0.23 | $7 |

| Space Heater | 1500/1000*3*0.39193 | $1.76 | $53 |

So, yeah, the electric blanket or throw is way cheaper!

There are many different ways you can edit home improvement videos. Here are some:

This is pretty simple to do. You can just add a bunch of photos to the video track of your video editor, animate each photo (many video editors can do this automatically), add some music to the music/audio track, and render the video. The result can be pretty good but it doesn’t really give a sense of the amount of effort or process involved. Here’s an example clip.

If you have a short video, leaving the speed at normal 1x speed might be okay. But, if your video is long, people will get bored very quickly. Since most home improvement projects take longer than 30 seconds, I don’t recommend this option, unless you are maybe adding a voiceover that explains what you are doing in the video.

Another option is to just timelapse the entire video. Some home improvement projects can take all day. Many people, including myself, will just leave a camera somewhere that will take many still photos at a set interval to create a timelapse video. You can also record an entire day’s worth of video, which I’ve also done using a WyzeCam mounted on a wall. Timelapsing an entire video is as easy as speeding up the video clip. The downside is the audio is also sped up and often doesn’t sound good so you usually mute the audio and optionally add some background music. Here’s an example.

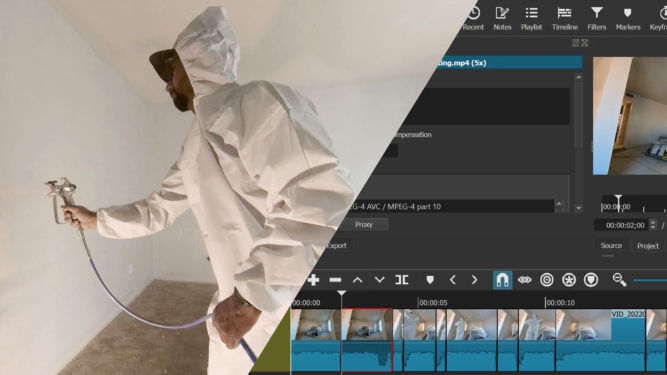

Another option is to timelapse (speed up) certain parts of the video and leave the other parts at regular 1x speed. This is definitely more work but I personally find this better than just speeding up the entire video. However, I find the best effect is when the regular speed segments are ones that have a high volume, e.g. when you’re using a tool that makes a lot of noise (drilling, jackhammering, cutting, etc). Here’s an example.

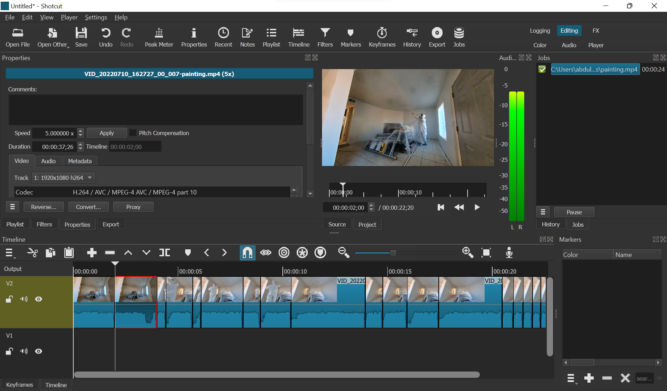

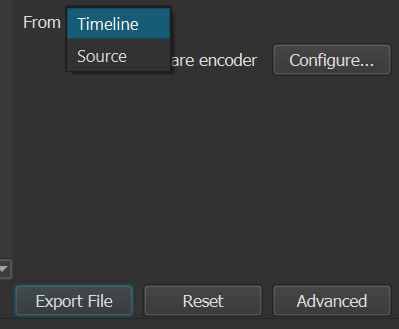

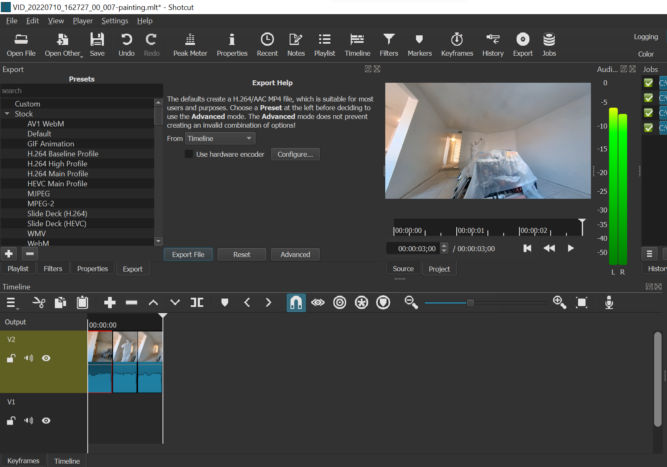

I normally use Corel VideoStudio to edit videos but for this purpose, I find Shotcut to be easier to use. Shotcut, which is free, shows the waveform very clearly, runs faster and hasn’t crashed on me yet. The UI takes some getting used to but once you get the hang of it, it’s pretty simple to us. Here are the steps I follow in Shotcut to create this type of video:

Another option is to create a video from a selection of 1-second segments. Some segments will probably have high volume, e.g. drilling, jackhammering, cutting, etc. , Others may not, e.g. lifting, cleaning, drawing lines, etc. Again, I find this much easier to do in Shotcut than in Corel VideoStudio. Here’s an example.

Here’s how I do it in Shotcut:

If you end up with a bunch of video clips that you want to merge and you don’t need to apply any transitions or effects, you can merge them almost instantly with LosslessCut.

One of my properties is in an HOA. Though many people dislike HOAs and having to pay a monthly HOA fee, one huge benefit of being in an HOA is you never have to deal with unsightly views from the street. If someone violates the CC&Rs, they are fined and forced to stop. This improves everyone’s curb appeal including the neighborhood as a whole. For me, and many others, that’s valuable. But, my other properties are not in an HOA. And, unfortunately, people have very different ideas of what looks good. One neighbor put down pavers himself but was either lazy or didn’t know how to do it right. As a result, the pavers are uneven and weeds are growing everywhere. Another neighbor beheaded their tree leaving a 5′-tall trunk in the middle of their front yard surrounded by probably one of the cheapest rocks you can find – gray gravel. This is bad, but it’s nothing compared to another property of mine where one immediate neighbor is a mechanic who works on cars in his driveway almost 24/7. The neighboring property is a triplex owned by a slumlord who doesn’t appear to care one bit that her ghetto tenants are destroying her property as long as she collects the very low rent that she can get. Their lawn is destroyed because sometimes they park their cars on it. Their garbage bins are always overflowing and are a fly magnet. And if that’s not enough, the other immediate neighbor covered their lawn that meets my property line with concrete and illegally parks a beat-up pickup truck on it. They also leave a grill, used car parts, engine oil, and various other garbage along their side of the property line. As a result, no matter how much I improve my property, being sandwiched between two ugly neighbors significantly ruins my property’s curb appeal. Reporting code violations to the City is useless as they never do anything. Putting up a fence helps but the municipal code limits how tall they can be. Fortunately, there is no height limit on trees as there are 2 and even 3-story-tall trees in nearby front yards. So, one solution I decided on to block the unsightly neighbors is by creating a fence made up of Cypress trees. These trees are super low maintenance, evergreen, the leaves don’t fall and create a mess that you have to clean up all the time, and they grow in a very predictable manner (straight up) so you don’t need to worry about stray branches hitting your eaves or roof.

I bought the 5-gallon trees from a nearby nursery for $75 each. In Spring, you can get them at Costco for $40. You can rent a flatbed pickup truck from the Home Depot for $19 for 75 minutes. These trucks are ideal because you can lower the tailgate and the sides as well, making the loading and unloading of trees, or anything for that matter, much easier.

Along the east-facing fence, I had to dig holes in a section where there was no concrete. Digging holes is a PITA for sure. But, using the right tools like a gas-powered auger makes it less of a PITA. In the photo below, I made a square hole by making 4 small holes at each corner using the auger, then another hole in the middle, and then removed the remaining dirt.

Along the west-facing fence, I had previously poured concrete so I had to cut squares in it for the trees to go in. After backfilling with dirt, I covered the dirt with cement board to be used as weed fabric (regular weed fabric is useless), and then poured a layer of ginger rock.

Here’s how the west side looks. The fence boards are red-stained and cost about $3 each from Home Depot. I ran a 1/2″-diameter tube from the back of the building for irrigation. Connected to that tube are smaller tubes for drip irrigation directly at the root of each tree. The photo below is from before the concrete was pressure washed.

Here’s how the east side looks. You can still see the junk cars next door but after these trees grow tall and thick, my tenants will be shielded from the unsightly views next door and the curb appeal will continue to improve and there will be a clear delineation between my property and the neighboring ugliness.

I continued the fence/tree design alone much of the east side to block as much of the neighbors as possible.

Within 5 years, the trees will be as tall as the 2-story buildings and have a much wider diameter.

So there you have it. One way to block trashy neighbors while not violating most municipal codes.

Concrete in your home is everywhere. From your driveway, garage floor, patio, porch, and backyard, everyone has concrete. Unfortunately, concrete is porous and can easily get dirty. Oil, dirt, and stains from all sorts of things can permeate and discolor concrete seemingly permanently. Pressure washing concrete with a high-pressure washer won’t even remove the discoloration. To protect your concrete from stains, you’ll need to seal it. If your concrete is already ugly or if you want to change the way it looks, you’ll need to apply a coating on it, e.g. epoxy. But, in order for any coating to adhere and not peel off, you’ll need to prepare (prep) the surface very well. This is the most important step when renovating concrete. Do it right, and you’ll vastly improve and transform the look of your concrete and your home. Here’s an example before and after picture of a garage floor I renovated.

This is not the step where you want to be lackadaisical. Following are different ways you can prep your concrete surfaces.

You can pour acid on bare concrete and scrub it around. However, the chemicals are toxic, smelly, and harmful.

The concrete prep attachment is for etching bare concrete floors to prepare for adhesive coatings. This option is much better than using acid, IMHO. But, it’s a bit more expensive. I think I rented it for $140 for 4 hours from the Home Depot. It’s a bit tiring to use because the polisher likes to move in one direction so you need to force it to go in the other direction.

Make sure you choose the concrete prep attachment and not the coating removal attachment picture below. Both look similar but the latter is for removal of mastics, glue, adhesives, thinset epoxies and paint from interior concrete.

Another option is to grind the concrete down. This, however, requires getting down on the ground and can take a long time. You’ll also need to use a shopvac to suction the dust as this will product a ton of dust. Concrete dust is harmful because it contains silica which can mess with your lungs. If you have a small area to grind or if you need to grind edges, this tool is handy.

This commercial-grade concrete grinder can be rented at the Home Depot. It grinds down concrete high spots, removes sealers and thin mil paints, removes mastics and preps floors to accept new coatings.

This tool should also be used with a concrete grinder dust vacuum.

This tool can be rented from Sunbelt Rentals for $270 / day. This tool works by blasting media (shot) at the concrete to scour the surface. This is one of the best ways to prepare concrete. However, what’s annoying about it is you have to periodically pick up the shot media that escapes the tool.

You can hire a company, like this one in Stockton, California, to prep your concrete for you. This tool uses a combination of water and shot media.

I just finished renovating an entire 2-bedroom, 1-bathroom apartment and totally remodeled the kitchen from a U layout to an L layout with an island. Here are some before and after pics and step-by-step pictures showing how I did it.

Here’s how I renovated the apartment step by step:

The doors were all beat up so I replaced them with new ones.

For the kitchen and bathroom, use 20 amp outlets, otherwise, use 15 amp outlets.

All HVAC registers were beat up so I replaced them all.

To remove the baseboard, first, cut the caulk using a utility knife. You can also use an oscillating tool.

Then, I like to use a mallet and a special tool that makes it easy to pry the baseboard away from the wall. It has a large surface area to minimize damaging the wall as you pry the baseboard off.

Most of the time, you can reuse the baseboard. But in this case, mine was so beat up that it wasn’t worth it. Plus, for a rental property, it’s better to install a tile baseboard.

First, I made holes in the wall and ceiling between studs and joists using a 4″ hole saw. I then inspected the area behind the wall and ceiling to ensure no obstacles were present. It there were obstacles, I could easily patch the holes using the circular cutout pieces.

I then ran yellow romex wiring. Yellow wiring can support 20 amps. I could have used a higher gauge (thinner, lower 15 amp-rated) wire since this is for a ceiling fan in a bedroom.

Where the ceiling fan would go, I cut a rectangular piece of drywall using a small reciprocating saw. I could have used a jigsaw as well. The cut was made in such a way so that I could reuse the piece to patch the ceiling when done.

After installing a ceiling fan bracket between joists, I pulled the wiring to the bracket.

I then wired up the switch…

…and patched the ceiling using the existing drywall.

For the circular holes, I patched them using the circular drywall cuts created when making the holes. I screwed a piece of furring strip behind each hole as pictured.

And then screwed the circular drywall cuts to the furring strip.

The vanity top was made of cultured marble. I just broke it into small pieces using a sledge hammer.

I then cut up the wood vanity using a reciprocating saw and a demolition blade.

I removed the caulk on the wall using a oscillating tool following by an orbital sander.

In the kids’ bedroom, there were many holes in the wall. Some parts of the wall were patched very poorly. I decided to a large section of drywall. I tried using a drywall cutout tool but it was very noisy and it was hard to cut a straight line.

I ended up just using a reciprocating saw and oscillating tool to cut the drywall.

I screwed in the drywall using drywall screws.

I put mesh tape along the edges of each piece of drywall. This helped hold the drywall mud in place where there were large gaps.

For the drywall mud, I used premixed joint compound so I didn’t have to mess with mixing powdered drywall with water.

I then used an orbital sander to smoothen the mud. This produced a lot of dust, but that was okay because I was going to remove the carpet and paint the walls afterward.

To demolish the old kitchen cabinets, I first unscrewed and removed each cabinet door.

I hated the old kitchen layout. The half wall and ceiling cabinets made the dining and kitchen areas very small.

The ceiling cabinets can easily be removed by unscrewing them from the ceiling and wall.

I used the backyard to temporarily store all the construction debris.

I removed the heavy marble countertop by breaking it up into small pieces using a sledge hammer.

You should definitely wear a full face mask when doing this to prevent small objects hitting your eyes or face.

Just for fun, I used my 24V electric chainsaw to cut up the base cabinets.

After unscrewing some screws that fastened the base cabinets to the wall, I was able to pull out the cabinets.

To remove the pony wall, I drilled a bunch of 4″ holes in it so I could see if there was anything dangerous behind it.

I was then able to demolish it.

The 24V electric chainsaw was handy for quickly cutting some thick pieces of wood.

For safety, I hammered down any nails that were sticking out.

The wall was soggy because there was a small leak that was never detected. I had to cut out the soggy drywall so I could replace it.

To remove the old floor tile, I used a jackhammer with a chisel bit. Since there had been a leak in the kitchen, the tiles were easy to remove.

In the living room, however, it was a little harder to remove the tiles.

In general, separating the tile from the floor was easy.

What was difficult was moving the broken tile outside because it was heavy.

I put the broken tile in bags out front.

I first tried removing the thinset mortar using a scraper attachment on my jackhammer. But, that proved slow and very tiring…

… so I rented a heavy duty jackhammer and cart. This was much easier but still a lot of work. Note to future self: don’t ever do this by yourself. Just pay someone to do it.

I used painter’s plastic to cover large areas like windows. It’s a very thin plastic.

I sprayed glue around the perimeter of the window.

And stuck the plastic to the wall.

I removed excess plastic by trimming it off with a utility knife. Make sure to use a new blade.

I could then just peel off the excess plastic.

I did the same to cover outlets and switches, although I alter realized it would’ve been easier to cover small areas using blue masking tape.

You can then trim the excess tape with a utility knife so when you’re done painting…

…you can just remove the tape.

To paint the walls and ceiling, I used the Graco Magnum X5 Airless Paint Sprayer. Setting it up and cleaning it up was a hassle, but once it was primed and ready to go, it worked very well and made painting very quick and easy with good, even results.

I first painted primer on the colored walls since the colors were dark. I painted two coats.

Try to move quickly to avoid runny paint.

Painting ceilings is easy with a paint sprayer like this.

Once the primer dried, I painted the whole apartment. A fresh coat of paint really does make a big difference by making the place look new and clean.

But spray paint particles can really get on your face and glasses.

Dirty walls suddenly look new again.

Painting ceilings would have really been hard without a paint sprayer.

Using a utility knife, I cut the carpet in 2 or 3′ sections.

I then rolled it and the underlayment padding up and strapped it from unraveling using duct tape.

I then removed the tack strip along the perimeter since I was going to install tile over the concrete.

Husky contractor clean-up bags are great for disposing of construction debris.

Using an angle grinder, I trimmed any tacks/nails that were stuck in the concrete.

Here’s a close-up.

I hate multi-turn water valves. I paid a plumber to replace them with 1/4-turn valves.

I bought 12″x24″ large tiles.

I paid someone to install the tile. First, they removed the tile around the electric fireplace.

Then they put cement board around the firstplace as backing for the tile.

They scraped the floor to remove any uneven spots from thinset.

They mopped the floor to remove excess dust.

They mixed the thinset and troweled it on the floor before laying down the tile.

I later noticed they were using the wrong type of thinset so I had them use thinset for large format tile (LFT).

For some tile, they’d cut it using a manual tile cutter.

They used little red plastic things to ensure adjacent files were level with each other.

I chose a terracotta color for the fireplace surround tile.

They applied the grout.

Then wiped it off the tile itself.

And mopped off any excess grout.

Before installing the cabinets, I had to patch the wall where there had been a water leak. I marked the stud locations using a stud finder.

Using a level, I drew lines where the studs were.

Sometimes, I’d cut drywall using a jigsaw.

Other times, I’d cut it by first scoring it using a utility knife…

…snapping it…

…and scoring the other side.

It’s actually easier and creates a straight cut with no dust.

I had to screw in some 2x4s to existing studs so I’d have a frame to screw the drywall into.

I dry-fitted the cut drywall panels.

And occasionally I’d have to mark edges that didn’t fit…

…so I could trim them using a rasp.

I screwed the drywall into the studs using drywall screws such that the screw heads would be slightly recessed so they wouldn’t be seen after patching with drywall mud.

I added mesh tape along all seams/joints to hold drywall mud (joint compound).

Then I applied joint compound.

I had to cut open the ceiling and reroute the exhaust vent.

I removed the old rigid vent.

And installed a flexible vent.

The exhaust went was moved to the wall above where the range would be.

IKEA delivered the kitchen cabinets.

To install the wall cabinets, we had to fasten metal brackets to the wall, sometimes using drywall anchors. We also had to cut some of the brackets using an angle grinder.

IKEA cabinets come flat-packed and must be assembled.

Fastening wall cabinets to the wall is easy because you can hang them on the bracket and adjust their position before finalizing where they’d go.

The base (floor) cabinets/drawers come with short plastic legs. This is good so that if the floor is wet, the wooden cabinets wouldn’t get wet.

I decided to run additional wiring to a new switch to control a new ceiling fan I planned to put in the kitchen.

We cut a hole in one of the wall cabinets where the exhaust vent would go.

All IKEA cabinet boxes are white. For end cabinets werhe a side will be exposed, we screwed a finished panel to the side.

We installed the over-the-range microwave.

And then attached the cabinet doors.

We screwed in the door handles and attached the kickboard.

For IKEA kitchen cabinets, I had to cut 3/4″ thick plywood to put on top of the base cabinets. For non-IKEA cabinets, you can use 1/2″ thick plywood.

I screwed the plywood in through the metal holes at the top of the cabinets.

I decided to buy a new range because the old was in very bad condition.

I bought the quartz countertop from Granite Expo and paid them to install it. In the picture below, they cut the quartz and sanded the edges.

Cutting quartz can produce a lot of dust.

The inside edges were also smoothened.

One guy cut a hole in the plywood for the sink. I decided to go with an undermount sink. The lip of the sink would sit on the plywood but below the countertop. The would ensure the sink would stay in place.

They also made a hole in the countertop for the sink. Like marble, quartz countertops are very heavy.

They put construction adhesive on the plywood before laying down the countertop.

The corner seam between the two adjacent countertop slabs was straight, not diagonal. Getting the two slabs to be perfectly level with each other was tricky. The guy screwed a screw up from under and through the plywood to push up areas of the countertop so it would be level with the adjacent slab. The other guy was applying silicone caulk around the inside edge of the sink.

One of the guys was smoothening and polishing one cut end of the backsplash.

They glued the backsplash to the wall.

They were nice enough to clean up after themselves.

Unlike other appliances, I had to install the range plug by screwing it to specific terminals on the range.

I decided to replace the 220V outlet with a new one. I turned off the circuit breaker first.

I first secured the sink to the countertop by turning a large plastic piece. No special tools were required.

I then screwed the hot (left) and cold (right) water supply lines to the new 1/4-turn valves.

I made a bead of plumber’s putty…

…and put it around the sink hole…

…and then put the sink strainer on it. The plumber’s putty helps prevent leaks.

I then secured the sink strainer by screwing it to a complementary part underneath the sink.

The black PVC drain pipe stuck out too far so I cut it. After installing the garbage disposal, I applied PVC glue around the pipe…

…and inserted a threaded coupling to it.

I then connected the garbage disposal outlet to the drain inlet coming out of the wall. I hate fooling around with PVC so this time, I used flexible p-trap by SimpleDrain. It comes

It’s so much easier to install than PVC p-traps. Instead of screwing on flimsy PVC nuts, SimpleDrain uses an adjustable metal clamp.

This is what the old kitchen looked like.

And this is the new. One of the cabinets was missing when I took this photo. As you can see, remodeling the kitchen with a new layout really makes the kitchen feel bigger.

I decided to replace the kitchen and dining room ceiling lights.

I bought a gray vanity to match the gray kitchen cabinets. I had to assemble the vanity.

Without the countertop, it was lightweight.

It actually took a long time to assemble. After assembling the frame and installed the 2 doors, I had to assemble 4 drawers.

Once that was done, I could install the heavy countertop by first applying a bead of glue to the top perimeter of the vanity frame…

…and to the wall where the backsplash would go.

I like this countertop because the sink and backsplash are integrated making installation easier and minimizing leaks.

So, I messed up. When I painted the ceiling and walls, I chose a color that looked good in a certain light but not in others. In the evening, and in soft white lighting (slightly yellow), the walls appeared to have a blueish hue to it. It made the rooms psychologically feel a bit cold and that drove me crazy. I decided to repaint the ceiling and walls. But, this time it was hard because I had to be careful not to get paint on the new tile and kitchen cabinets.

The new color I decided on was

This color is neutral and perfect.

I taped some masking paper to the top of the tile baseboard.

I covered the floor with a large drop cloth and covered the kitchen cabinets with large plastic and cardboard. Notice the difference in the ceiling color.

Preparation takes a long time but spray painting is quick and easy.

It’s hard not getting paint on yourself. My glasses and watch had many paint specks on them.

I then had to go back and paint some missed areas.

It’s always satisfying, though, to remove masking tape to reveal the finished product (as long as the masking tape doesn’t rip and can easily be pulled off).

I was too lazy to texture part of the wall above the backsplash. It’s not that noticeable though.

Now that I was really done painting the walls and ceiling, I installed the ceiling fans in each bedroom.

Yay! It works 🙂

To clean the windows, I first sprayed Sprayway foaming glass cleaner on them.

Then, I used a blade to scrape the entire surface to remove any dirt, paint overspray, etc.

Then, I wiped the windows using a microfiber cloth. Below are before and after pics.

I had unpainted garage walls. The builder would just install drywall and patch holes but that’s it. I ended up painting the walls plain white (the color of primer).

I hate painting ceilings.

Having an extension pole allowed to reach high areas.

The garage floor was heavily discolored and looked dirty. There were all sorts of stains. To beautify it, I first sprayed water on it.

Then, I used a orbital floor polisher tool with a floor prep attachment. This attachment has a bunch of very coarse tabs like rough sandpaper. It etches the surface and scratches the hell out of it. The tool tends to want to move to the right all the time so you need to force it to stay put or go left. It’s way better than using chemicals like muriatic acid.

When I was done etching the garage floor, I pressure washed it and let it dry overnight.

The next day, I applied 1-part epoxy along the perimeter. The specific epoxy I used was Behr 1 gal. Slate Gray Self-Priming 1-Part Epoxy Satin Interior/Exterior Concrete and Garage Floor Paint. We’ll see how long it holds up. Another option was to use Behr Granite Grip but that’s a lot more work to apply.

This epoxy is like a primer. When you roll it on, it easily covers up any discoloratino. Two coats may be needed. It’s very satisfying to easily transform an ugly garage floor into one that looks brand new. Plus, painting a floor is much easier than painting a wall or ceiling. The color of the epoxy looks almost like untinted concrete.

When the epoxy dried, I installed a LED shop light with motion detection.

In one of the other garages (the triplex has 3 garages), I tried applying Behr Granite Grip. Not only is Granite Grip more expensive, I had to use a texture sprayer connected to an air compressor to get good results.

I then had to use a texture roller to even out the material. The results were good but not worth the time, effort and cost for a rental property.

The tenants I kicked out had a dog they never cleaned up after. There was dog shit everywhere. When they left, they removed the large pieces but the concrete was still discolored by dog shit that baked in the Stockton, California sun and permeated into the porous concrete. This was brand new concrete that I had put in the year before. Pressure washing with a high-PSI commercial pressure washer was inadequate. I decide to apply the same treatment I applied to the heavily stained garage floor. In this photo, I was etching (scratching) the surface.

I then pressure washed the concrete.

After the concrete dried, I applied epoxy to the joints using a wide paint brush.

And then I rolled on epoxy to the rest of the concrete.

When I had the concrete put in, I didn’t want it to go all the way to the fence for drainage purposes. But, if you leave dirt along the fence, you’ll end up with a jungle of weeds, which is exactly what happened. To fix this, I first took used my jack hammer to break up concrete from old fence posts.

I bought a PVC pond liner, which is 14.5-mil thick, and cut it a little longer than some 8-foot-long 2x4s.

I stapled the liner to the 2×4.

I made some holes in the 2×4 and hammered in some long galvanized stakes to hold the wood in place along the edge of the concrete. The pond liner covers some of the dirt. Along the fence, I stapled some pond liner that also covered some of the dirt. In between and overlapping the two pond liner pieces, I put cement board. This will prevent weeds from growing while still allowing water to drain.

Finally, I powered 3/4″ ginger rock to keep everything in place and for aesthetics.

To get rid of all construction debris, I cut up some things into small pieces and put all small garbage in clean-up bags.

I rented a box truck from Home Depot, loaded garbage into a 4-wheel cart, and used it to move junk to the truck.

The process worked very well. Luckily there was a ramp.

At the dump, I threw everything off the edge of the platform like the toilet…

…and the old doors.

Periodically, a huge bulldozer would come and push all the garbage away.

I had to clean the truck to avoid a cleaning fee.

Dumping the many bags of broke tile was extremely tiring. I’ll make sure to pay someone to do that next time.

I paid about $150 to the dump to dispose of a truck-load full of garbage and around $50 for the truck rental.